Modern Warehouses: The Nerve Centers of Ecommerce

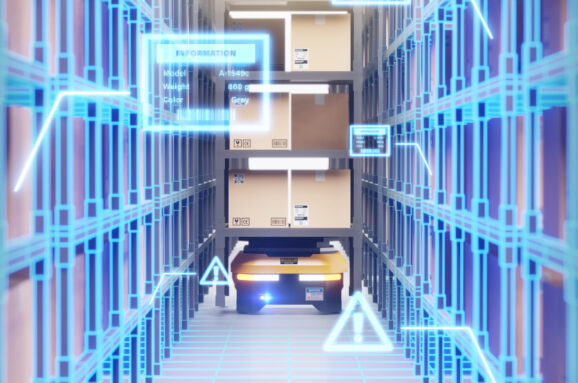

The modern warehouse is likely to be shaped by advances in technology and changes in consumer behavior. The evolving landscape of e-commerce and global trade, fulfillment centers have emerged as vital hubs of efficiency. The market size of the logistics industry in the U.S. increased faster than the economy overall over the past five years. These modern warehouses are no longer just vast storage spaces; they have become the nerve centers of the supply chain. As we look into the future, we find ourselves on the brink of a logistics revolution, where fulfillment centers are poised to undergo dramatic transformations driven by cutting-edge technologies and revolutionary concepts. Here are a few potential developments that could impact how fulfillment centers operate in the coming years:

More than just a vast storage spaces.

- Smarter inventory management: With the help of sensors and data analytics, modern warehouses may be able to more accurately track inventory levels and anticipate demand. This could lead to more efficient use of space and resources, as well as faster order fulfillment.

- Faster delivery times: As consumers increasingly expect same-day or next-day delivery, fulfillment centers will need to find ways to speed up their operations. With a results driven team of dedicated drivers and dispatchers, we’re constantly monitoring the routes of our drivers at ITF Group to solidify our KPI’s with cross-docking times to keep drivers driving and not sitting.

- Sustainability initiatives: With growing concern about the environmental impact of e-commerce, modern warehouses may need to adopt more sustainable practices. This could include the use of renewable energy sources, more efficient packaging, and the implementation of circular economy principles to reduce waste. In addition to our warehouse practices, ITF Group maintains a fleet of over 250 trucks that are cycled every 5 years. By cycling our fleet for cleaner trucks, we continue to reduce carbon emissions each year.

- Artificial Intelligence (AI): AI algorithms analyze vast amounts of data, warehouses can make intelligent decisions in real-time. Predictive analytics can anticipate demand patterns, enabling more accurate inventory management and replenishment strategies.

Furthermore, Beyond technological advancements, sustainability is emerging as a critical focus in the future of fulfillment centers. As environmental concerns take center stage, companies are seek ways to reduce their carbon footprint and embrace eco-friendly practices. As we step into this new world of modern warehouses, we find ourselves at the cusp of unprecedented possibilities. By embracing these advancements, companies can achieve unparalleled operational efficiencies, improve customer experiences, and contribute to a more sustainable planet.